Llámanos

:

+8613539043381

Envíenos un correo electrónico

:

marketing@databeyond.com

Desafíos en el reciclaje de películas plásticas

Las películas plásticas, como las de LDPE, las películas de embalaje y las películas agrícolas, se encuentran entre los materiales más difíciles de reciclar. Su ligereza y flexibilidad provocan ondulaciones, enredos y trayectorias inestables en los sistemas de clasificación convencionales. En los flujos de residuos mixtos, las películas suelen enrollarse alrededor de rodillos o sensores, lo que genera tiempos de inactividad y elevados costes de mantenimiento.

La contaminación y las estructuras multicapa complican aún más el proceso. Muchas películas contienen adhesivos, tintas o capas compuestas como PET/PE, que son difíciles de separar con los separadores NIR estándar. Como resultado, los recicladores se enfrentan a una baja pureza, un bajo rendimiento y una baja rentabilidad, lo que limita el reciclaje a gran escala de residuos de películas.

La necesidad de una solución de clasificación óptica especializada

Los clasificadores ópticos tradicionales están diseñados principalmente para plásticos rígidos. Al procesar películas ligeras, la turbulencia del aire y la reflectancia inconsistente provocan frecuentes errores de clasificación. Para lograr una recuperación eficiente de las fracciones de película, el sistema debe garantizar una alimentación estable, un reconocimiento preciso y una expulsión precisa, requisitos que los diseños estándar no pueden satisfacer por completo.

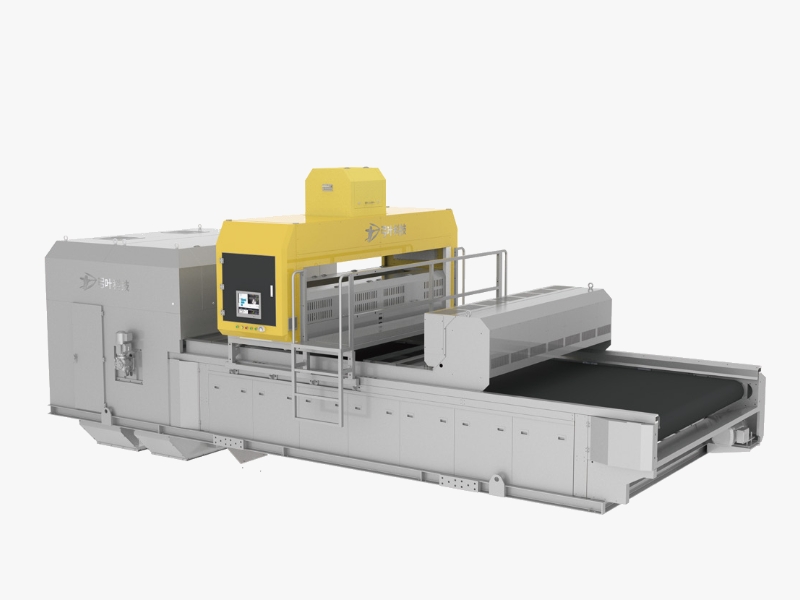

Presentamos FASTSORT-FILM de DATABEYOND

Para abordar estos desafíos, DATABEYOND desarrolló FASTSORT-FILM, un clasificador óptico hiperespectral basado en IA diseñado específicamente para el reciclaje de películas y plástico blando.

⭐1. Diseño aerodinámico para materiales ligeros

FASTSORT-FILM adopta una innovadora estructura aerodinámica con flujo de aire activo sincronizado con una cinta transportadora de alta velocidad (3,5–4,2 m/s). Esto garantiza un flujo uniforme y distribuido de materiales ligeros y minimiza las turbulencias. El depósito de recolección optimizado estabiliza aún más la trayectoria de expulsión, reduciendo la flotación y la deriva de la película.

⭐2. Sistema de reconocimiento dual AI + SPEC

Al combinar el aprendizaje automático de IA con imágenes hiperespectrales (SPEC), FASTSORT-FILM identifica materiales por tipo, polímero y color con una precisión excepcional. El sistema dual distingue con precisión entre películas similares (PE transparente, PE tintado o compuestos multicapa) incluso en condiciones complejas.

⭐3. Alta precisión y rendimiento

Con un rango de tamaño aplicable de 50 a 300 mm, el sistema alcanza una precisión de clasificación superior al 90 %, superando con creces a las clasificadoras de film tradicionales. Su robusta estructura evita obstrucciones mecánicas y reduce el tiempo de inactividad, garantizando un funcionamiento estable y continuo.

Beneficios para las plantas de reciclaje y plantas de reciclaje de residuos sólidos urbanos (MRF)

Las fracciones de película de mayor pureza mejoran el valor del reciclado.

Menores costos de clasificación manual y mantenimiento.

Mayor rendimiento para el procesamiento a escala industrial.

Retorno de la inversión mejorado a través de un rendimiento estable y consistencia del rendimiento.

Ya sea integrado en una línea de residuos mixtos o en un sistema de clasificación de películas dedicado, FASTSORT-FILM proporciona una ruta comprobada para la recuperación de películas de plástico blando de alta pureza y alta eficiencia.

Acerca de DATABEYOND

Como el mayor proveedor chino de clasificadores ópticos basados en IA para sistemas de reciclaje, DATABEYOND cuenta con una amplia experiencia en aplicaciones globales de clasificación de residuos. Miles de sus sistemas operan en Japón, el Sudeste Asiático, Italia, Francia, Brasil y México, ayudando a los recicladores a alcanzar mayores objetivos de recuperación y circularidad.

Al combinar inteligencia artificial, imágenes hiperespectrales y precisión aerodinámica, DATABEYOND continúa redefiniendo cómo la industria del reciclaje maneja materiales complejos como películas y plásticos flexibles.

Si está buscando una máquina clasificadora de películas, una solución de reciclaje de películas plásticas o un proveedor de clasificadoras de películas ópticas, comuníquese con DATABEYOND para obtener más información sobre cómo FASTSORT-FILM Puede optimizar su operación.

Dejar un mensaje

Escanear a WeChat :

Escanear a WhatsApp :