Llámanos

:

+8613539043381

Envíenos un correo electrónico

:

marketing@databeyond.com

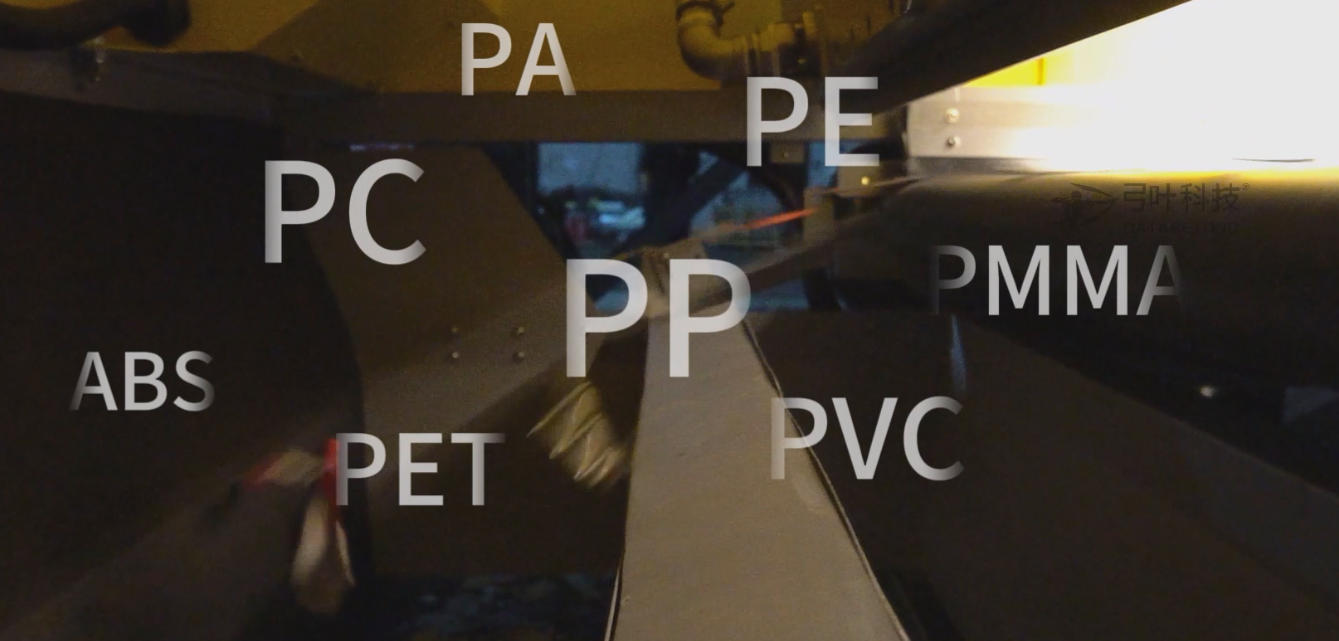

El mercado mundial del plástico reciclado para 2025 está en auge, pero la clasificación de las escamas de plástico doméstico —desde artículos de uso diario triturados hasta piezas de electrodomésticos trituradas— sigue siendo un costoso cuello de botella. Los recicladores se enfrentan a tres grandes problemas: mezclas de resinas complejas (PP, PE, PC, ABS y muchas más), una precisión de clasificación manual inferior al 40 % y un preprocesamiento costoso (lavado y secado), además de una pérdida de polvo del 8 al 12 % debido al triturado repetido. El reciclaje de alto valor a menudo parece inalcanzable.

DATABEYOND FASTSORT-COMPACT (clasificador óptico de escamas de plástico mixto) soluciona estos problemas directamente. Sus sensores multiespectrales con IA identifican cientos de tipos de plásticos con alta precisión, mientras que la clasificación por color y material es crucial para identificar usos finales de alto valor, como el reciclaje de plástico mixto o el ABS automotriz.

Lo más innovador: Procesa escamas de gran tamaño de 6 mm a 50 mm mediante una cinta transportadora de alta velocidad, sin lavado, secado ni trituración repetida. Esto elimina por completo los costos de preprocesamiento y reduce drásticamente la pérdida de polvo. Con una capacidad de 2 a 3 toneladas/hora, satisface las necesidades de reciclaje de plástico de electrodomésticos a gran escala, y su diseño de una sola pasada ahorra mucho espacio en comparación con los sistemas tradicionales.

Para los recicladores, especialmente las pequeñas y medianas empresas que dominan el sector, estas mejoras suponen una reducción tangible de costes. La reducción del consumo de agua, energía y mano de obra para el preprocesamiento reduce las cargas operativas, mientras que el material preservado minimiza el desperdicio de materia prima valiosa. El resultado son flujos de trabajo de clasificación más eficientes que clasifican plásticos mixtos complejos de alta pureza según la demanda.

A medida que las políticas ambientales de 2025 se endurecen y las empresas del sector downstream demandan más contenido reciclado, FASTSORT-COMPACT convierte los problemas de clasificación en eficiencia operativa. Descubra cómo transformar los flujos de plástico mixto en recursos de alto valor en la página de productos de DATABEYOND.

Dejar un mensaje

Escanear a WeChat :

Escanear a WhatsApp :